IIoT Technology

- Industrial IoT Solution Architecture and Product Innovation

- Edge Data Collector - PLC-Side Protocol Converter

- Edge Data Collector - PoE-Powered Device Sensing Gateway

- CODESYS Edge Controller - Real-Time SoftPLC and SoftMotion Controller

- ThinClient Visualizer - Centralized Management of Multiple Displays

- Secured Edge Analyzer - Intelligent Platform with Azure IoT Edge

- Predictive Edge Analyzer - Diagnosis and Preventive Maintenance Platform

- Fault-Tolerant System - Continuous Availability for Zero Downtime

- Fault-Tolerant System - Full Virtualization and Self-Protection

- Cloud Network Management System - Cloud Management System for Predictive Maintenance and Optimize Operation

- Network Security Pack - Efficient Cyber Security Guard from Network Edge

- LoRaWAN Gateway with MQTT and Node-RED - Low-Power Wide Area Network for Wireless Communication

- Zero-Touch Mass Router Deployment System - Advantech Router and Gateway Remote Management, Monitoring and Provisioning Platform

- Cellular Connection and Conversion for Smart Metering - IEC 101/104 Protocol Conversion and Remote Management Platform

- OPC-UA Suites and Protocol Conversion Gateway - Fieldbus and Industrial Ethernet Interconnection in OPC UA Environment

- Critical Video Service Guarantee System - Congestion Management and Guarantee Video Service System

- Auto-Configuration Backup and Restore System - Auto-Configuration for Easy System Administration and Operation

Industry 4.0

- Industry 4.0 / iFactory SRP Solutions

- Activating Industry 4.0 with Advantech's Modular Solutions

- Machine Condition Monitoring and Predictive Maintenance

- EtherCAT Motion Control Solution

- Automatic Optical Defect Inspection Solutions

- Track and Trace Solution for Product Traceability

- Integrated iFactory Cloud Solution

- SRP - AI-based Optical Inspection

- Intelligent Vision Inspection System

- SRP - DeviceON Management Services

- SRP - M2I/ Intelligent CNC Machine Management Solution

- SRP - Assembly Line iWorkstation

- SRP - Factory Energy Management Solution

- SRP - Factory Environmental & Waste Monitoring

- SRP - Overall Equipment Effectiveness (OEE)

- SRP - Warehouse Management Systems

- SRP - iFactory Cloud MES

- Machine-to-Intelligence (M2I) Solutions for Energy and Environment

- Smart Self-Healing Grid with Energy IoT Solution

- The great integration of wireless sensing and communication devices

- Intelligent Sensing Technology

- SRP - Intelligent Water Management Solution

- SRP - Wind Power Monitoring & PHM Solution

- SRP - Solar Power Management Solution

- SRP - Pump and Motor Monitoring & PHM

Industry 4.0 / iFactory SRP Solutions |

Industry 4.0 is transforming manufacturing worldwide. Factory management needs assistance as they either upgrade existing facilities, or establish new ones that take advantage of Industry 4.0 optimization. Advantech’s IoT solution architecture strategy enables the development of iSensing devices, edge intelligent servers, and iFactory Solution Ready Packages (SRPs) that help customers embrace Industry 4.0.

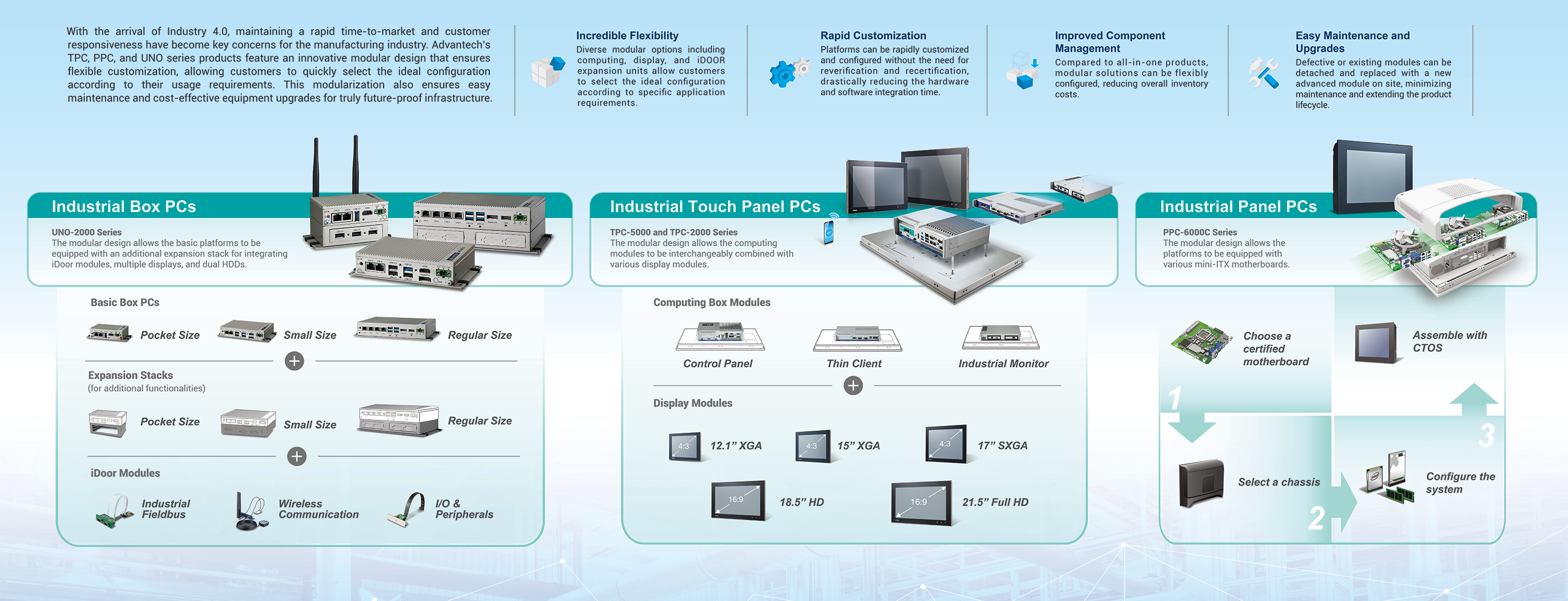

Activating Industry 4.0 with Advantech's Modular Solutions |

With the arrival of Industry 4.0, and the resulting shift in market demands, a rapid time-to-market and customer responsiveness have become key concerns for the manufacturing industry. The innovative modular design of Advantech’s latest TPC, PPC, and UNO series products offers increased flexibility and customization ability that allows customer to select the ideal configuration easily and quickly according to their usage requirements. This modularization also enables easy maintenance and cost-effective equipment upgrades for truly future-proof infrastructure.

Machine Condition Monitoring and Predictive Maintenance |

Predictive and preventive maintenance have become indispensable parts of Industry 4.0. Machine condition monitoring (MCM) systems upgrade consumable and damage replacement practices as well as periodic maintenance activities to preventive or even predictive maintenance.

With Advantech’s WebAccess/MCM software, customers can quickly install Advantech’s data acquisition modules and implement predictive maintenance in their factories. This helps improve equipment uptime, performance, and safety while greatly reducing maintenance costs.

EtherCAT Motion Control Solution |

The trend of industrial IoT has changed the face of traditional production lines and led to the birth of a new generation of smart factories, allowing automation technology represented by motion control to be extensively applied. Future motion control will become faster, more precise, and network-based, and can be divided into two areas: industry-based equipment applications and a network of edge computing devices combined with cloud service platforms. This will further be integrated with information technology to achieve the vision of smart manufacturing.

Advantech's complete EtherCAT motion control solution includes the EtherCAT main station controller card in the industrial computer has a large number of flexible industry-specific APIs; the integrated MAS controller comes with Advantech's Motion Studio software, highly integrated with a simple Basic programming environment to satisfy customers' demand on rapid development; the PAC can integrate control, data processing, and network connection on a single control platform, and provides CODESYS that supports the IEC 61131-3 PLC programming language standard, satisfying the multi-purpose and high expansion requirements of automation applications.

Automatic Optical Defect Inspection Solutions |

In the inspection of parts and components, since the manufacturing quality of the workpiece surface directly affects both the appearance and function of the final product, it is necessary to pass inspection prior to shipping. To meet this requirement, Advantech provides a non-contact automatic optical inspection system for inspecting the surface of workpieces.

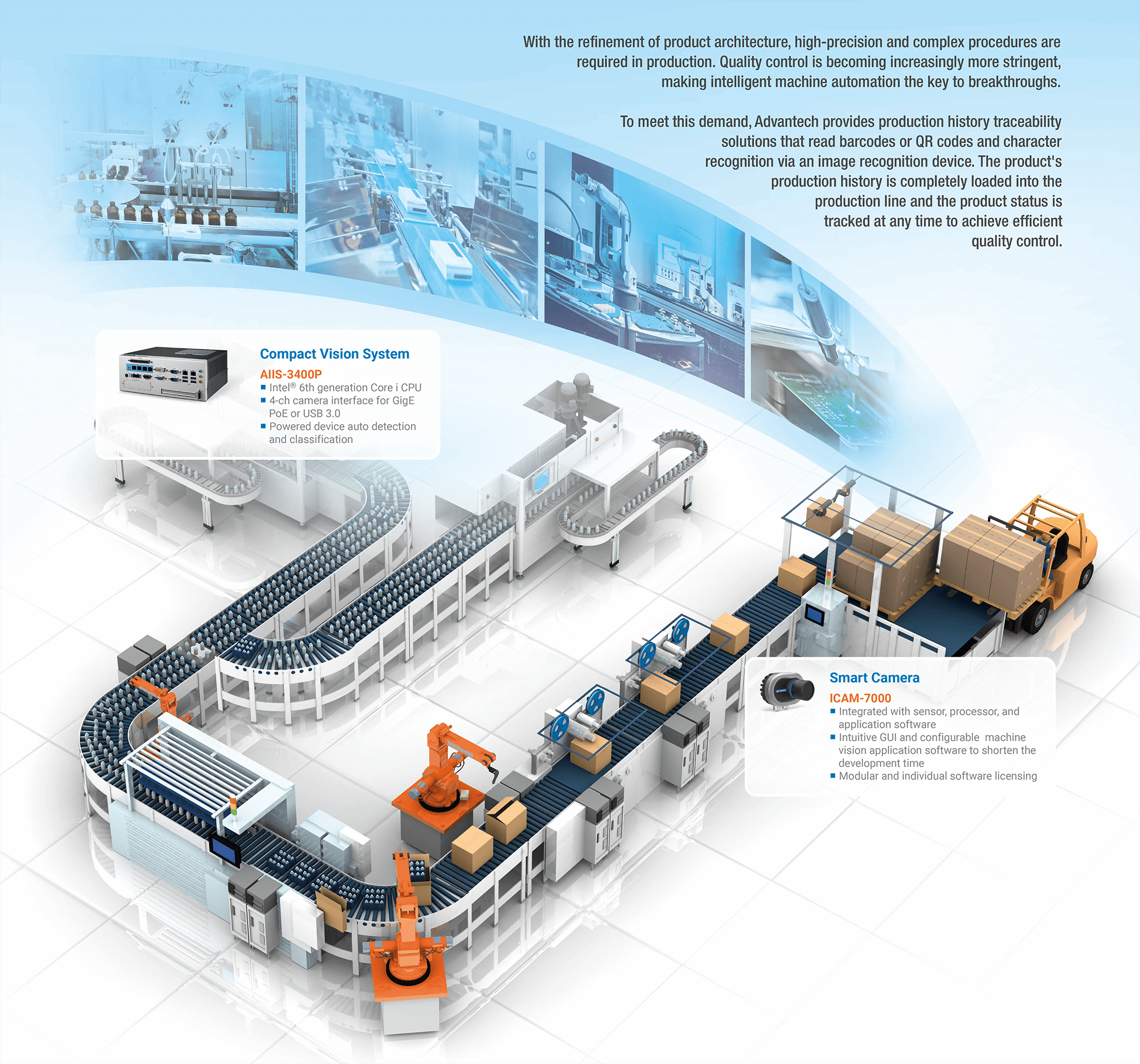

Track and Trace Solution for Product Traceability |

With the refinement of product architecture, high-precision and complex procedures are required in production. Quality control is becoming increasingly more stringent, making intelligent machine automation the key to breakthroughs. In this context, machine vision plays an important role in improving production efficiency and the tracking of production records to achieve intelligent production.

To meet this demand, Advantech provides production history traceability solutions that read barcodes or QR codes and character recognition via an image recognition device. The product's production history is completely loaded into the production line and the product status is tracked at any time to achieve efficient quality control.

| © 1983-2018 Advantech Co., Ltd. | | | RSS & Subscription | | | Site Map | | | Privacy Policy |